120 m³/day Integrated Domestic Wastewater Treatment Unit

Belongs to:

Details

- 产品描述

-

I. Process Selection

The wastewater treated in this project is typical municipal mixed sewage, characterized by a BOD/COD ratio exceeding 0.5, indicating good biodegradability. Therefore, the proposed treatment process includes the A2O biological contact oxidation system combined with MBR and disinfection. This process is simple to operate, requires low operating costs, is easy to manage, delivers excellent treatment performance, and ensures stable operation. It is currently a well-established technology for domestic wastewater treatment, effectively guaranteeing that the effluent meets discharge standards.

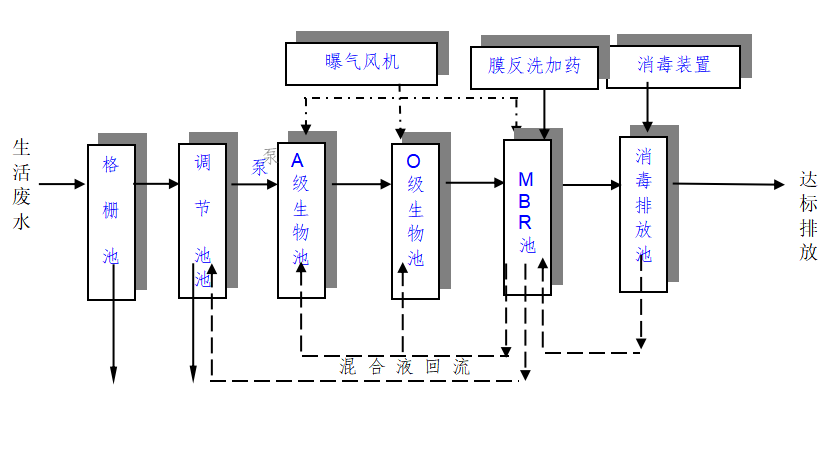

II. Process Flow

See the figure below:

III. Process Description

1) Wastewater Treatment Processes

Wastewater first enters the bar screen well, where it is screened to remove debris before flowing by gravity into the equalization basin. The purpose of the equalization basin is to regulate both the quantity and quality of the wastewater. To prevent suspended solids from settling at the bottom of the basin, perforated aeration pipes are installed along the basin floor, employing intermittent aeration.

Hospital wastewater has a relatively high organic content, with a BOD5/CODcr ratio of 0.5, indicating good biodegradability. Therefore, adopting biological treatment methods to significantly reduce the organic pollutant levels in the wastewater is the most cost-effective approach. Given the high concentrations of ammonia nitrogen and organic compounds in the wastewater—especially organic nitrogen—during the biological degradation of organic matter, the organic nitrogen is often released as ammonia nitrogen. Since ammonia nitrogen is also a critical pollutant control parameter, the wastewater treatment process employs an anaerobic-aerobic A2/O biological contact oxidation system. This system divides the biochemical tank into two distinct sections: an A-stage tank and an O-stage tank. In the A-stage tank, the wastewater, boosted by sewage lift pumps from the equalization basin, undergoes biochemical treatment. Due to the high organic load in the influent, microorganisms here operate under anaerobic conditions. These facultative microorganisms convert organic nitrogen into ammonia nitrogen while simultaneously using organic carbon sources as electron donors to transform NO2⁻-N and NO3⁻-N into molecular nitrogen (N2). Additionally, they utilize some of the organic carbon and ammonia nitrogen to synthesize new cellular materials. As a result, the A-stage tank not only effectively removes organic pollutants, reducing the organic load on the downstream O-stage tank to facilitate efficient nitrification, but also leverages the high organic content in the wastewater to carry out denitrification, ultimately mitigating nitrogen-induced eutrophication pollution. After passing through the A-stage tank, although the wastewater still contains residual organic matter and elevated ammonia levels, these conditions are ideal for further organic oxidation and decomposition. Moreover, as the carbonaceous degradation nears completion, the environment becomes conducive for robust nitrification to occur smoothly. This is precisely why the O-stage tank is specifically designed to ensure that nitrification proceeds efficiently, thereby achieving thorough removal of both organic compounds and ammonia nitrogen from the wastewater.

The effluent from the A-level tank flows by gravity into the O-level tank, where treatment is carried out entirely by autotrophic bacteria (nitrifying bacteria). These bacteria utilize inorganic carbon sources produced during organic matter degradation—or even carbon dioxide from the air—as their primary nutrient source, converting ammonia nitrogen in the wastewater into NO2⁻-N and NO3⁻-N. Part of the effluent from the O-level tank is sent to a sedimentation tank for solid-liquid separation, while the remaining portion is returned to the A-level tank for internal circulation, enabling denitrification. Both the A-level and O-level biochemical tanks are equipped with packing materials, and the entire biological treatment process relies on a diverse community of microorganisms that thrive on these surfaces. In the A-level tank, dissolved oxygen is maintained at around 0.5 mg/L, whereas in the O-level tank, dissolved oxygen is kept above 3 mg/L, with an air-to-water ratio of 15:1.

A portion of the effluent from the O-level biochemical tank is returned to the A-level tank, while another portion flows into the vertical-flow sedimentation tank for solid-liquid separation.

The effluent from the sedimentation tank, after solid-liquid separation, can be directly discharged following disinfection in the disinfection pool.

The sludge settled in the sedimentation tank is treated by our company's state-of-the-art pulse air-lift device, which was introduced using advanced technology. A portion of the sludge is lifted back to the A-stage tank for internal circulation, while another portion is transferred to the sludge storage tank. After being concentrated and disinfected in the sludge storage tank, the sludge is either transported offsite for disposal or safely buried.2) Sludge Treatment Process

Typically, there are two common methods for sludge treatment at small-scale wastewater treatment plants: one is mechanical dewatering to concentrate the sludge, and the other is sludge drying. However, while mechanical dewatering requires significant capital investment from the owner, sludge drying can negatively impact surrounding hygiene conditions. Fortunately, since this process includes a sludge digestion system that generates only minimal sludge volume, the sludge produced by this project undergoes only simple concentration before being manually removed annually and subsequently used as agricultural fertilizer off-site.

IV. Process Facilities

1. Class A Biological Treatment Pond (Anoxic Pond)

Purpose of setup:

Due to the high organic content in the wastewater, with a BOD5/CODcr ratio of 0.5 indicating good biodegradability, the design adopts the biofilm process.

Because hospital wastewater contains high levels of organic nitrogen, which is released as ammonia nitrogen during biological degradation, the concentration of ammonia nitrogen in discharged water tends to increase. Since ammonia nitrogen itself is a key pollutant-control indicator, an anoxic tank is added upstream of the contact oxidation pond. In the anoxic tank, nitrate from the recirculated mixed liquor and organic carbon sources from the influent are utilized for denitrification, converting NO2⁻ and NO3⁻ in the incoming water into N₂—a process that effectively removes nitrogen while simultaneously reducing ammonia nitrogen levels as organic matter is degraded.

Design features:

Equipped with high-efficiency bio-elastic packing, it also features hydrolysis and acidification capabilities, while simultaneously being adjustable as an O-stage biological oxidation pond—enhancing biochemical retention time and boosting the system's overall treatment efficiency.

The pool is designed with a steel structure and is buried underground.

2. Class O Biological Treatment Pond (Biological Contact Oxidation Pond)

Purpose of setup:

This pond is the core component of the wastewater treatment system, divided into two stages. In the first stage, under a relatively high organic load, biochemical degradation and adsorption processes occur simultaneously, driven by a diverse microbial community attached to the packing material, effectively removing various organic substances from the wastewater and significantly reducing their concentration. In the second stage, with a lower organic load, nitrifying bacteria take over, breaking down ammonia nitrogen in the wastewater under oxygen-rich conditions—while also further lowering the COD level, ultimately achieving thorough purification of the effluent.

Design features:

The pond consists of components such as the pond body, packing material, water distribution system, and oxygenation aeration system.

The biological contact oxidation method primarily relies on the biofilm process while also incorporating features of the activated sludge method: (1) It boasts a higher biomass concentration per unit volume compared to the activated sludge process, resulting in a higher organic loading rate, shorter contact time, and superior treatment efficiency. This makes it ideal for reducing the size of treatment structures, minimizing land use, and lowering infrastructure investment costs. (2) Since no sludge return is required, sludge bulking is virtually eliminated, simplifying operation and maintenance. (3) The system exhibits strong resistance to shock loads. Thanks to the abundant biofilm growing on the packing material, this method adapts effectively to fluctuations in organic load—and even maintains good performance under intermittent operating conditions. As a result, it is particularly well-suited for treating pharmaceutical wastewater with uneven discharge patterns. (4) Biofilm formation and microbial acclimation are straightforward. Typically, biofilm development occurs within 7 to 5 days, and after about 20 days of acclimatization, the system can be put into full operation.

The packing material used in the pond is an elastic, three-dimensional composite filler, which boasts a large specific surface area and a long service life.

Easy to form biofilm, corrosion-resistant, and prevents clumping or clogging. The packing material freely expands in water, effectively slicing through bubbles in multiple layers, thereby significantly enhancing aeration efficiency. Additionally, the packing is installed in a cage-like structure, making it convenient for removal, maintenance, and inspection.

The pond is divided into two stages, creating a gradient in water quality degradation to achieve excellent treatment results. At the same time, the design incorporates appropriate flow-guiding and turbulence-control measures, making the overall layout more rational and efficient.

The aeration pipeline in the pond is made of high-quality ABS material, which is highly resistant to corrosion. The aeration heads are micro-porous, ensuring they remain unobstructed while delivering excellent oxygen utilization.

The pool is designed with a steel structure and is above ground.

3. Sedimentation Tank

Purpose of setup:

Perform solid-liquid separation to remove the biofilm and suspended sludge shed from the biochemical tank, ensuring thorough purification of the wastewater.

Design features:

Designed as a vertical-flow sedimentation tank, it exhibits excellent sludge degradation performance.

Using a triangular weir for effluent discharge ensures stable water quality.

Sludge is periodically discharged to the sludge pond using the air-lift method, and an air-lift reflux system is installed. A portion of the sludge is returned to the Class A biological treatment tank for nitrification and denitrification, which not only reduces sludge production but also enhances the removal of ammonia nitrogen from the wastewater.

The pool is designed with a steel structure and is buried underground.

4. Disinfection and Discharge Pond

Purpose of setup:

Manufactured according to the national standard "TJ14-74," it ensures an effective disinfection contact time of 30 minutes or longer. In this unit, E. coli and other bacteria are most effectively eliminated, resulting in effluent bacterial counts of fewer than 100 CFU/L. An overflow discharge outlet is also installed in this unit.

Design features:

The disinfection pool is equipped with a disinfection device and diversion plates, utilizing contact disinfection. This dosing method offers convenient, simple, and safe features, and the disinfected water is then discharged into the municipal sewage pipeline.

The pool is designed with a steel structure and is buried underground.

5. Sludge Digestion Tank

Purpose of setup:

The sludge from the sedimentation biofilter is periodically discharged into the sludge pond for anaerobic digestion. At the same time, an intermittent aerobic mixing method is employed, which can reduce the volume of excess sludge by more than 70% through the digestion process. The supernatant from the sludge pond, along with activated sludge, is returned to the anoxic zone, while the excess sludge is regularly removed—typically twice a year. Biogas generated in the equalization tank, anoxic zone, aerobic zone, and secondary settling tank is collected via ABS pipes and routed to a high-altitude downspout, preventing any potential secondary pollution.

Design features:

The pool is designed with a steel structure and is buried underground. It features an integrated aerobic sludge digestion system.6. Fan

Purpose of setup:

Provides oxygenation and aeration, as well as mixing, sludge lifting, and sludge digestion in A/O-level biochemical ponds and equalization basins.

Design features:

Set up 1 unit.

The fan design features a compact size, low noise, ample airflow, and consistently reliable performance.

7. Automatic Control Cabinet

The main unit uses Sanshui electrical control cabinets, while other key electrical components are sourced from Chint products, ensuring fully automatic operation and control. It will be installed inside the fan room (to be provided by the buyer).

V. Process Characteristics

Employing a mature A/O biochemical treatment process, it effectively removes organic pollutants from wastewater and delivers excellent nitrogen removal performance, ensuring compliance with emission standards.

It possesses excellent resistance to shock loading, enabling it to adapt to variations in water quality and volume.

Adopting the sludge pre-return reflux nitrification process significantly reduces sludge generation.

Adopting a new type of packing material, it promotes rapid biofilm formation, boasts a long service life, and delivers quick treatment results.

Fully consider the possibility of secondary pollution and minimize its impact to the greatest extent possible.

Adopting centralized control and automated operation, it is easy to manage and maintain, enhancing system reliability and stability.

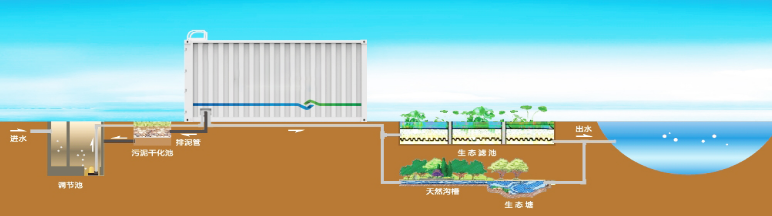

The system's treatment facilities are entirely located beneath the ground, occupying no surface area—allowing for landscaping while also providing excellent frost protection.

Previous page

Next page

Other Products

Jiangsu Degao Internet of Things Technology Co., Ltd.

Consulting

Recruitment

Address

No. 158, Xinsheng Road, Nantong, Jiangsu, Maipu Technology Park

Subscription Number

Service Number

Mobile phone QR code

Copyright © 2025 Jiangsu Degao Internet of Things Technology Co., Ltd.

Powered by www.300.cn | Tag |