Intelligent Seismic-Resistant Vortex Flowmeter

Belongs to:

Details

- 产品描述

-

Overview

The intelligent, earthquake-resistant vortex flowmeter is primarily used for measuring the flow rate of fluid media in industrial pipelines—such as gases, liquids, and steam—across a wide range of applications. It features low pressure loss, an extensive measurement range, and high accuracy. When determining volumetric flow under varying process conditions, its performance remains virtually unaffected by factors like fluid density, pressure, temperature, or viscosity. Additionally, the device contains no moving mechanical parts, ensuring exceptional reliability and minimizing maintenance requirements. Furthermore, the meter constant maintains long-term stability.

The instrument features a piezoelectric stress-type sensor, offering high reliability and capable of operating within a temperature range of -20°C to +300°C. It provides both analog standard signals and digital pulse outputs, making it easy to integrate with digital systems such as computers—thus making it a highly advanced and ideal flow measurement device.

Measurement Principle

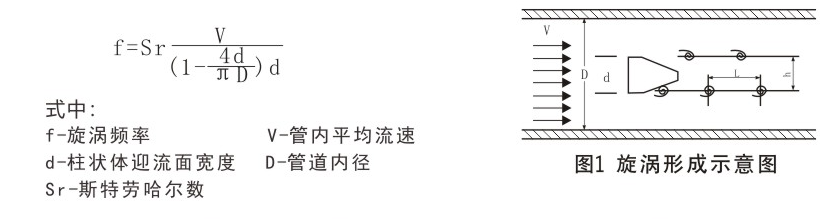

When a cylindrical bluff body is inserted vertically into a fluid, vortices are alternately generated on either side of it. As the fluid flows downstream, these vortices form a vortex street known as the Karman vortex street, as shown in Figure 1. The bluff body that triggers the formation of the vortex street is called the vortex shedding body. Experiments have demonstrated that the frequency of the vortices is directly proportional to the flow velocity, and can be expressed by the following equation:

Experiments have shown that an asymmetric vortex street can maintain a stable state when the distance \( h \) between two adjacent vortices satisfies the condition \( h/L = 0.281 \), where \( L \) is the distance between two vortices within the same row. Moreover, when the fluid Reynolds number \( Re \) ranges from 5,000 to 150,000, the Strouhal number \( Sr \) remains essentially constant. Therefore, under conditions where the width \( d \) of the vortex shedding body and the Strouhal number \( Sr \) are fixed, the frequency \( f \) of the vortex shedding is directly proportional to the average flow velocity of the fluid.

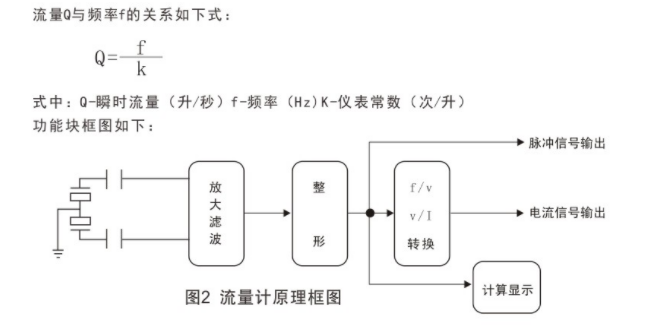

Fast response is directly proportional—specifically, it’s proportional to flow rate but independent of parameters such as pressure, temperature, and density. When vortices are generated on either side of the cylinder, the sensor experiences an alternating lift force perpendicular to the flow direction, generating a corresponding signal. The frequency of this lift variation matches the vortex shedding frequency. After the sensor sends the signal to a converter for amplification and shaping, a pulse signal linearly proportional to the flow velocity is produced—ready either for direct output or further conversion into a standard 4-20mA signal.

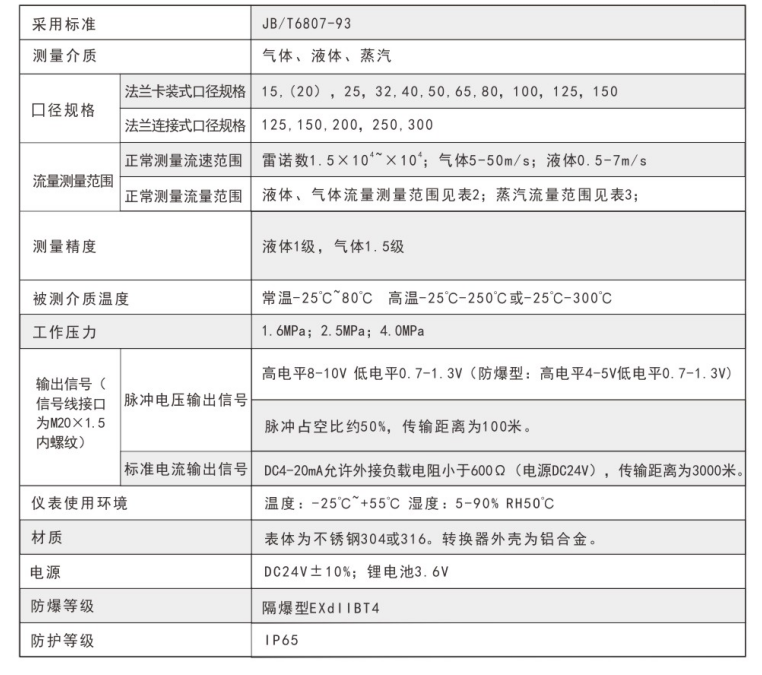

Technical Specifications

Main Technical Parameters

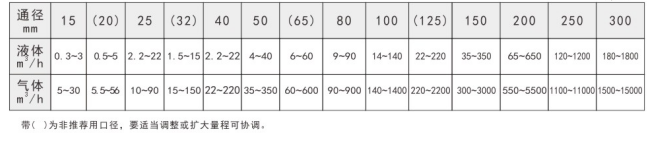

Liquid and process gas flow ranges

Other Products

Jiangsu Degao Internet of Things Technology Co., Ltd.

Consulting

Recruitment

Address

No. 158, Xinsheng Road, Nantong, Jiangsu, Maipu Technology Park

Subscription Number

Service Number

Mobile phone QR code

Copyright © 2025 Jiangsu Degao Internet of Things Technology Co., Ltd.

Powered by www.300.cn | Tag |